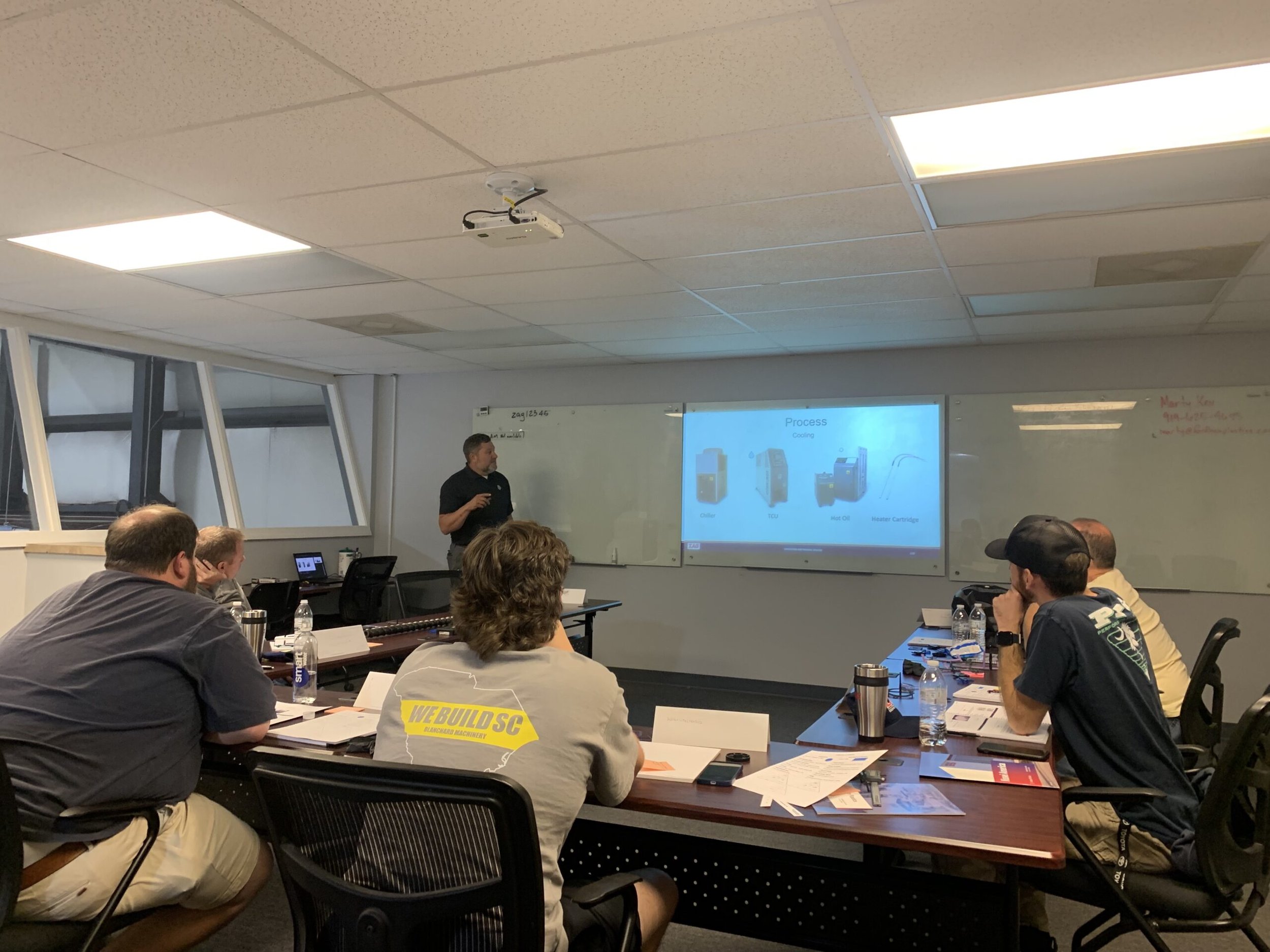

Injection Molding Process Training

Fordham Plastics sister company ZAG Equipment Sales is proud to host training at their warehouse in Gibsonville, NC. Our 'Injection Molding Process Training' is held by our Industry Expert, Marty Key.

We Offer Four Core Classes:

Introductory - Elements of Injection Molding

Intermediate - Principal Concepts of Injection Molding

Intermediate - Mold Setting

Advanced - Process Development Class

Each class is approximately $2000 for three full days, and includes both a hands-on and classroom learning experience, and will prepare you for a career in Injection Molding. Secure your spot for our next class today!

Class Summaries

ZAG Consulting Services strives to improve our customers’ profitability by solving today’s challenging manufacturing headaches.

Our team of plastics professionals, with decades of experience in all facets of plastics manufacturing – training, mold design, equipment and resin selection, process improvement, manufacturing support, and more – delivers solutions resulting in measurable production and process improvements.

From training process technicians to solving complex organizational challenges, ZAG Consulting Services offers industry expertise helping our customers achieve their goals.

ZAG Consulting Services

Process Improvement

• Machine Selection

• Material Handling Instruction

• Mold Set Up Instruction

• Process Improvement

• Cycle Time Reduction

• Instrumented Molding Implementation

• Machine Testing and Assessment

Manufacturing Support

• Project Management

• Manufacturing Cell Layout

• Lean Manufacturing

• 5S Methodology

• Failure Investigation

• Corrective Action

We Can Help You With:

Validation

• Validation

• Tool Launch

• Tool transfer

• Process Development

• Design of Experiments (DOE)

• Qualifications - 1Q, OQ, PQ

More About Our Industry Expert, Marty Key

With over 20 years of injection molding, consulting and training experience, Marty Key helps customers improve molding operations and profitability. Offering a range of consulting services, Marty delivers proven solutions from eliminating processing headaches to solving organizational challenges.

Marty's extensive expertise and unique technical skills result in measurable manufacturing improvements.

• Training

• Part Validation

• Mold/Plant Design Review

• Process Improvement

• Manufacturing Support

• Quality Systems

Contact Marty.

marty@fordhamplastics.com

(919) 625-4695

“Marty is a great instructor. Fully explains everything and allows ample time for questions. Can’t think of anything I’d like to see improved!

I would highly recommend this class!”

— Jim Piermarini, Technical Precision